Our Commitment to Safety

Our goal is to get Everyone Home Safely, every day. This includes our people, contractors, customers, and the community. We’ll focus on preventing injuries and ill-health to provide a safe and healthy workplace. We’ll also play our part as a responsible business by meeting our environmental responsibilities and adopting sustainable practices, making our world more productive. By working together and taking care of each other we can get Everyone Home Safely:

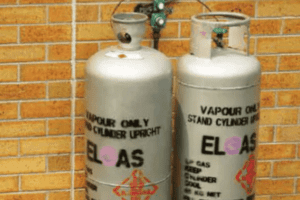

We are prepared for emergency situations anytime, anywhere We will help and train customers in the safe handling and use of LPG, and support them whenever an emergency situation arises Our team of professional engineers and experienced technical managers are ready to assist with the design, installation and servicing of all ELGAS equipment We focus on quality principles, values and responsibilities that advance our ability to always deliver products and services that safely and reliably meet customer expectations

Being Safe with LPG Gas

LPG is an extremely flammable, liquified gas stored under pressure in various gas bottle sizes and gas tanks. LPG gas is used as a residential, commercial and light industrial energy source.

LPG Gas Storage

LPG Gas Installation

Safe Use of LPG Gas

Forklift Gas Bottle Safety

ELGAS business customers who rely on LPG for their forklift fleets need to follow strict rules to safely refill and/or exchange forklift gas bottles.

Safe forklift LPG cylinder refilling

Safe forklift LPG cylinder exchange

Safe forklift LPG cylinder decanting

Safe LPG cylinder decanting

Safe Handling of BBQ Gas Bottles

ELGAS – through SWAP’n’GO – has been powering outdoor Aussie barbeques, heaters and camp stoves for a generation.

Gas Leak Detection

LPG Gas Storage & Installation

BBQ Food Safety

LPG Gas Bottles During Cyclones, Floods & Bushfires

The ELGAS Emergency Helpline is staffed by trained professionals and available 24 hours a day, 7 days a week, and 365 days a year. Call 1800 819 783 for gas leaks or any emergency.

LPG Gas Bottle Safety – Cyclone and Floods

Bushfires and LPG Gas Bottles

Keeping your home and business safe

From gas leaks to what to do in a fire or flood, our LPG Safety eBook is here to prepare you for an emergency. For businesses, our local technical team is available to provide your staff with emergency response safety training.