Two approaches

LPG gas cylinders can be refilled in two ways:

Decanting: In service stations, LPG cylinders are often refilled by transferring gas from the source container until it vents excess gas. The venting occurs since a small vent screw allows excess gas to escape and prevent the cylinder from overfilling.

By Weight: For this method, LPG cylinders are placed on a scale, and the operator inputs the tare weight. Depending on the cylinder’s weight capacity and size, the electronic filling scale will transfer gas into the cylinder and shut off the valve as soon as the desired full weight is reached.

Gas bottles and cylinders are often made of welded steel, aluminium, and composites. Their rigid nature and high-pressure capacity make them refillable and reliable in various applications.

ELGAS LPG cylinders come in portable cylinders ranging from 3.7kg to high-capacity industrial sizes, such as 210kg and more. All these sizes are refillable, but gas refilling should only be done by professionals and must not be attempted by untrained individuals.

Improper refilling or using unproven methods to refill your LPG bottles at home may result in overfilled cylinders and lead to serious incidents when exposed to different temperatures.

Refill by weight

LPG cylinders are refilled in many ELGAS service locations using an electronic filling scale. These scales have a filling hose connected to a solenoid valve, which closes when the LPG reaches the desired weight.

Pros:

Accuracy: Filling by weight is more precise as the LPG’s gross weight is continuously measured electronically. Its automatic functions help in preventing underfilling and overfilling of all cylinders.

Safety: A properly calibrated and maintained scale can ensure operations are within safety standards.

Compliance: Electronic scales are more accurate and precise than decanting. They also meet most regulatory standards, as scales provide a clear, measurable, and standardised way to perform gas bottle refills.

Efficiency: Automating the filling process significantly speeds up the refilling process, eliminates human error, and maximises efficiency.

Cons:

Cost: Using electronic scales and automatic filling systems requires stations to purchase expensive equipment. Maintaining the equipment can also increase overall expenses.

Technical Requirements: Operating an electronic filling scale requires thorough training and skilled personnel to operate the machinery, perform routine maintenance, and calibrate the electronic scales annually.

Infrastructure: Refilling a gas bottle by weight should only be done in a controlled environment. Temperature and pressure may affect the scale’s accuracy.

A more controlled environment is needed to ensure the scales’ accuracy isn’t affected by environmental factors like temperature and pressure.

Refill by decanting

When refilling a gas bottle by decanting, the service station transfers gas from a larger supply tank into smaller consumer gas bottles. Decanting relies on the difference in pressure between the supply tank and the empty cylinder to transfer the gas.

Pros:

Simplicity: Decanting uses less equipment than filling by weight and is more straightforward. It also requires less automation as human operators manually close the filling valves.

Lower Initial Investment: Since decanting requires less equipment, service stations can start filling empty tanks with less capital and leverage faster turnarounds.

Flexibility: Decanting can be performed in various locations and remote areas.

Cons:

Less Accurate: Decanting heavily relies on visual indicators to close the valve—particularly the venting of excess gas via the vent screw. Because of this, the amount of gas transferred significantly varies and may lead to underfills or overfills.

Safety Risks: Overfilling beyond the required ullage (20% of volume) exerts too much pressure on the gas bottles. When exposed to direct heat or higher ambient temperature, the gas could expand, further increasing the internal pressure. This increases the potential for leakage.

Skill Requirement: Safety regulations and practices require operators to have sufficient training and certification. This is necessary to perform the refill and handle gas bottles safely. This lack of automation means higher expertise is required and increased reliance on human skills.

Environmental Factors: Ambient pressure and temperature all slightly influence the behaviour of the gas during transfer, complicating the operation and possibly affecting accuracy.

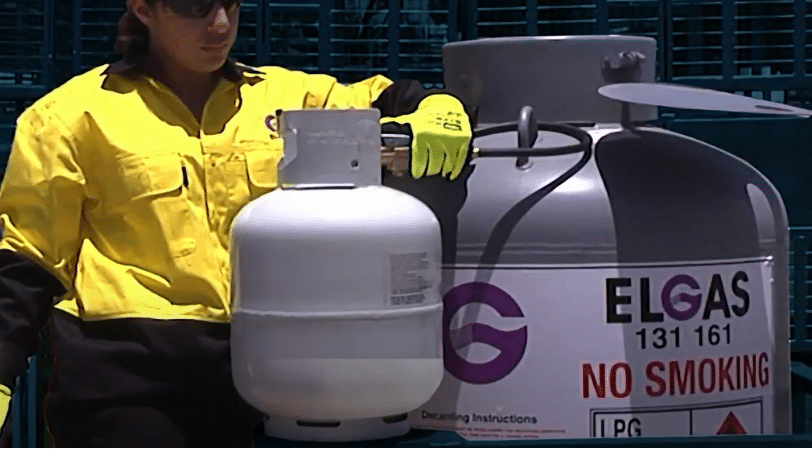

See VIDEO (Disclaimer: This video on how to Fill a Gas cylinder is only a supplement and refresher for trained individuals and professionals. Untrained individuals must not attempt LPG decanting.)

Current Inspection Date Required to Fill Gas

No matter which of the LPG gas cylinder refill methods is used, the cylinder must have a current inspection date. The refill technician is responsible for checking the inspection date stamped into the neck ring of the gas cylinder before refilling it.

Out-of-date gas cylinders cannot be refilled until re-inspected and stamped with a new inspection date.

How to Fill a Gas Cylinder Refill Using Digital Scales

Using digital scales helps ensure proper and safe refill of LPG gas cylinders based on weight. When the total weight equals the empty weight plus the appropriate LPG gas cylinder refill weight, the gas cylinder refill is complete.

The scales are set for each individual refill LPG gas cylinder based on its empty (tare) weight and the desired LPG gas cylinder refill content weight when full.

How the Scales Work

The cylinder manufacturer stamps the tare weight (empty weight) into the neck ring. The operator inputs the tare weight of the gas cylinder into the scale’s keypad. After inputting the weight, the technician connects it to the LPG supply to fill a gas cylinder. The digital scale automatically stops the refill of the LPG gas cylinder after reaching the target weight. This ensures an accurate gas cylinder refill and avoids dangerous overfilling or lost value through underfilling.

Faster Way to Fill a Gas Cylinder with Carousels

A side benefit of using scales to fill a gas cylinder is speed. The LPG supply line can be pump-driven to fill a gas cylinder faster. This is impossible with decanting, as the operator might be too slow to stop the gas cylinder refill process, resulting in dangerous overfilling.

Digital scales and pump-driven LPG also allow the use of high-speed carousels, like the SWAP’n’GO carousel in the accompanying image, to fill gas cylinders.

Even the keypad step can be automated in fully automated plants with gas cylinder refill carousels. The carousel digitally reads an RFID chip on the cylinder that contains the tare weight and the rest of the manufacturing specifications.

Decanting Method to Refill LPG Gas Cylinder

Technicians use decanting to transfer LPG gas from one cylinder to another. Decanting is the process most often used in petrol stations. After connecting the gas cylinder to a larger LPG storage tank, the trained operator begins to fill the gas cylinder until some gas starts leaking out of the loosened bleed screw. The operator should stop refilling the LPG gas cylinder as soon as liquid LPG starts coming out of the bleeder opening. The liquid LPG escaping is unmistakable, like a white cloud.

The digital scale method avoids this intentional gas venting into the atmosphere during the refill of the LPG gas cylinder.

Decanting can also result in either overfilling or underfilling an LPG gas cylinder and the correct refill of an LPG gas cylinder, depending on the gas cylinder and the operator filling it.

20% Oversized for Expansion

LPG vapour pressure rises with temperature.

The gas will expand if a gas cylinder is exposed to higher temperatures.

LPG cylinders are designed to be full while allowing 20% of the space, called “ullage”, for the natural expansion of the LPG.

Properly filled gas cylinders, with the required 20% ullage, should never have a problem.

Overfilling is Unsafe

When overfilled, a gas cylinder has less than 20% ullage, creating the possibility of the unwanted release of gas into the atmosphere through the pressure relief valve.

The pressure relief valve is incorporated into the main gas valve on the cylinder.

It’s a valve within a valve that is designed to vent gas in order to prevent dangerous overpressure situations.

So, overfilling combined with heat can result in gas venting from the pressure relief valve.

This is especially true in the warm Australian climate.

LPG refilling is NOT a DIY Procedure

Only trained technicians should attempt to fill a gas cylinder by either method. LPG gas cylinder refill is not a do-it-yourself handyman procedure and should never be attempted by untrained personnel.

The trained operators know all about the appropriate procedures, what personal protective equipment (PPE) to wear, the importance of the proper type of clothing (including material), proper cylinder grounding, static electricity hazards, ignition sources, fire protection and more.

In-depth safety training is mandatory for these technicians.

Doing it incorrectly could result in cold burns (liquid LPG is -42°C), fire, or even an explosion, as well as dangerous overfilling of a gas cylinder.

The simple message for people thinking about trying to refill their own gas cylinder -just DON’T do it!

Frequently Asked Questions

Is it cheaper to refill or swap my LPG bottle?

Refilling or swapping has pros and cons that affect the overall price and value. Consider whether you have the time to travel to the refill station, or is opting for SWAP’n’GO LPG gas bottles a more viable option?

Swapping LPG bottles saves you more time and money on smaller LPG gas cylinders. It’s also cheaper since you’re getting a new LPG bottle that’s well-maintained and passes our quality standards without spending the price of a new one.

However, SWAP’n’GO bottles are only available in two sizes – 3.7kg and 8.5kg. For larger sizes and industrial use, we exchange 45kg cylinders when empty or provide on-site refilling services.

How long does it take to refill an LPG bottle?

On average, an 8.7kg gas bottle takes 5-10 minutes to refill via decanting or an electronic filling scale. Larger cylinders take longer to fill. A 45kg cylinder, for example, can take 10-15 minutes to fill using a filling scale and 15-20 minutes to fill via decanting.

How long an LPG bottle takes to refill will depend on how well the filling equipment is maintained, what refilling method was used, the quality of gas accessories, and the pressure differential between the empty bottle and the supply tank (especially for decanting)

What happens if my LPG bottle is expired or damaged?

It is illegal and dangerous to fill and use expired and/or damaged LPG bottles. When maintaining our LPG bottles, we perform gas cylinder testing and re-stamp at approved test stations.

If you have an expired or damaged ELGAS LPG bottle at home, especially with visible damage to the gas accessories and valve, place it in a safe location and contact us at 1800 819 783 so we can swap it for a new one.

Expired LPG bottles undergo rigorous periodic overhauls every 10-15 years, including testing and safety checks such as:

- Degassing or disposing of gas

- Internal & external inspection

- Valve inspection or replacement of gas accessories

- Re-stamping

Can you dispose of my old LPG bottle?

ELGAS accepts 3.7kg and 8.5kg gas bottle disposal as part of our ongoing community service to ensure safe gas cylinder recycling. Our trained gas handlers will perform a gas cylinder test, remove any traces of residual gas, remove the valves, and either refurbish LPG gas cylinders that are within quality standards or puncture the LPG bottle for recycling.

You can contact us at 131 161, and we’ll provide handy tips on LPG safety until we arrive to pick them up or swap them for a full one.

What size LPG bottles can you refill?

Whether you’re using LPG bottles for cooking, gas heater, room heating, or outdoor BBQ, we provide gas bottle refills and cylinder exchange services for your bottles.

We provide on-site and in-house LPG refilling services for 15-18kg gas bottles and transport them via forklifts. For 45kg bottles, you can opt for a cylinder exchange and we’ll replace it with a full bottle at your location or refill it with our EASYGAS™ Bulk LPG Supply tankers.

Business and industrial cylinders such as 90-210kg LPG tanks can be refilled on-site with EASYGAS Bulk LPG Supply.

Where can I get my LPG bottle refilled?

You can find your local ELGAS stockist by visiting our locator or check out local SWAP’n’GO locations by typing in your suburb or postcode. For businesses and industrial settings with 45kg to 210kg gas cylinders or 0.5 tonne up to 50 tonne LPG tanks, we provide bulk LPG gas supply with site engineering support, equipment testing & maintenance, and supply continuity services.

You can also contact us at 131 161 to enquire about LPG gas refilling and cylinder exchange or switching to ELGAS and swapping out the old cylinder from your previous supplier. We’ve got you covered.