LPG Origin: How is LPG Made: LPG Production – Liquefied Petroleum Gas Production

What is LPG Made From – How LPG is Made

How is LPG gas made? The liquefied petroleum gas production (LPG production) starts with oil and gas wells.

What is LPG made from? Liquefied petroleum gas production involves refining crude oil or processing raw natural gas, both fossil fuel sources and the origin of LPG.

LPG originates and is stripped from the wet natural gas stream during natural gas processing and is a co-product of refining crude oil.

Whilst liquid under pressure when released from pressure at ambient temperature, it is gaseous.

It is stored and transported in LPG cylinders as a liquid under moderate pressure.

The gases produced in the liquefied petroleum gas production (LPG production) process are mainly propane, butane, and isobutane (what LPG is made from), with small fractions of other NGL gases.

LPG Constituents – What is LPG Made From

What is LPG made from? LPG is made from primarily of propane and butane, whilst the natural gas, the origin of LPG, primary constituent is methane.

Liquid petroleum gas is made (LPG is made) up of a number of gases under the LPG products label, including propane, butane, isobutane and mixtures of these gases and are also referred to as natural gas liquids – NGL.

Liquid petroleum gas is made (LPG is made) up of a number of gases under the LPG products label, including propane, butane, isobutane and mixtures of these gases and are also referred to as natural gas liquids – NGL.

Liquid petroleum gas is made – LPG is made of carbon and hydrogen atoms forming propane and butane whilst natural gas is made up of lighter methane, the simplest carbon and hydrogen molecule.

LPG is made from a group of flammable hydrocarbon gases that are liquefied through pressurisation and commonly used as fuel.

LPG Production – Where Does LPG Originate From

LPG production is from oil and gas wells, as it is a fossil fuel. 60% of LPG originates from natural gas processing “stripper plants” and 40% of LPG originates from the crude oil refinery process.

LPG production is from oil and gas wells, as it is a fossil fuel. 60% of LPG originates from natural gas processing “stripper plants” and 40% of LPG originates from the crude oil refinery process.

Liquid petroleum gas is made – LPG is made of a fossil fuel that does not occur in isolation.

The LPG production process (liquefied petroleum gas production process) starts with where LPG (propane) comes from – drilling oil and gas wells.

Then liquefied petroleum gas production process process continues with LPG originating from two LPG production process sources: natural gas processing and crude oil refining, the origin of LPG, is where it is a co-product of both.

LPG is made from a natural combination with other hydrocarbons.

How is Liquid Petroleum Gas Made? Liquefied Petroleum Gas Production

How is LPG Made – LPG Gas Production

Liquid petroleum gas is made (LPG is made) or LPG originates with natural gas processing and crude oil refining.

Liquid petroleum gas is made (LPG is made) or LPG originates with natural gas processing and crude oil refining.

This is a precursor to the liquefied petroleum gas production (LPG gas production) process and LPG products, as it separates the LPG from the LPG origin materials, raw natural gas and oil, which is the beginning of the LPG production process.

Liquid petroleum gas is made – LPG is made by stripping it from the “wet” natural gas stream as it comes out of the well or separating it from the crude oil during LPG refinery process.

The liquefied petroleum gas production (LPG production) process continues with LPG fractionation, to separate the LPG into its constituent gases: propane, butane and isobutane.

It is then placed in large LPG tanks and LPG cylinders for storage and distribution.

Liquefied Petroleum Gas Production – LPG Production Process – Summary

Liquefied petroleum gas production (LPG gas production) comes from refining crude oil or processing raw natural gas, all of which are sourced from fossil fuel.

Liquefied through pressurization, LPG is easier to store and transport.

Liquefied through pressurization, LPG is easier to store and transport.

Liquefied petroleum gas production (LPG production) occurs during fractional distillation of crude oil or is separated during natural gas processing.

To transport or store it, LPG gas needs to be liquefied under pressure.

LPG can be stored or transported in LPG gas cylinders or vessels.

If released from pressure, LPG gas is emitted.

LPG Production Process Description – Liquefied Petroleum Gas Production Description – Summary

An LPG – liquefied petroleum gas production (LPG gas production) process description summary starts with raw natural gas going through natural gas processing whilst the crude oil goes through fractional distillation of crude oil.

The NGL (natural gas liquids) condensate that results from both processes is then put through LPG fractionation to separate it into its constituent gases: propane, butane and isobutane.

The NGL (natural gas liquids) condensate that results from both processes is then put through LPG fractionation to separate it into its constituent gases: propane, butane and isobutane.

It is then ready for use, after the addition of ethyl mercaptan, as the safety odourant.

Liquid petroleum gas is made – LPG is made of propane, butane, isobutane and mixtures of these gases and are also referred to as natural gas liquids – NGL.

The LPG production process (liquefied petroleum gas production process) consists of the natural gas refinery process, fractional distillation of crude oil and LPG manufacturing involving these hydrocarbons.

What is Natural Gas Made of – LPG Origin

Natural gas is an origin of what LPG is made from, consisting of methane, propane, butane, isobutane, ethane, ethene, propene, isobutene, butadiene, pentane, pentene and pentanes plus, as raw unrefined natural gas.

Refined natural gas is made of almost entirely methane.

The LPG Name Game

What you get when you buy “LPG” can depend on the country you buy it in and/or the application.

In Australia, LPG is propane.

The exception is autogas, which can be a propane/butane blend.

In New Zealand, “LPG” is generally a propane/butane blend.

In the USA they call it “Propane”, which is what they sell, and generally don’t even use the term “LPG”.

LPG may also be referred to as a Natural Gas Liquids – NGLs – along with propane, butane, isobutane, ethane, pentane and pentanes plus (natural gasoline).

How is Cooking Gas Produced – How to Make LPG Gas

Cooking gas can be either LPG or natural gas.

LPG cooking gas is produced using the liquefied petroleum gas production process (LPG production process) that occurs during natural gas processing and oil refinery processing.

LPG cooking gas is produced using the liquefied petroleum gas production process (LPG production process) that occurs during natural gas processing and oil refinery processing.

We make LPG and natural gas cooking gas during natural gas processing.

Show Me My Price

Summary of the Liquefied Petroleum Gas Production – LPG Production Process

LPG is made from being found naturally in combination with other hydrocarbons.

The LPG gas production process (liquefied petroleum gas production process) consists of the natural gas processing, fractional distillation of crude oil and LPG manufacturing involving these hydrocarbons.

Liquid petroleum gas is made – LPG is made of a naturally occurring gas but propane does not occur purely by itself.

Liquid petroleum gas is made – LPG is made of a naturally occurring gas but propane does not occur purely by itself.

LPG is made from the LPG gas production process (LPG production process) and comes from fractional distillation of crude oil, the separation and collection of the propane from its petroleum base.

About 60% of LPG originates from natural gas processing followed by liquefied petroleum gas production (LPG production) from the raw natural gas that comes out of the wellhead.

The other 40% of liquid petroleum gas is made (LPG is made) from the fractional distillation of crude oil.

Liquefied petroleum gas production process (LPG gas production process) isolates from the hydrocarbon mixtures by its separation during natural gas processing or by the fractional distillation of crude oil.

Natural gas liquids (NGL) range obtained is from 1% to 10% of the natural gas flow.

Similarly, liquid petroleum gas is made (LPG is made) from fractional distillation of crude oil constitutes between 1% and 4% of the crude oil refining process.

Both LPG is made (LPG production) beginning by drilling oil wells.

Following the liquefied petroleum gas production process (LPG gas production) , LPG is stored and distributed as a liquid under pressure until used, at which point it is utilised as either a liquid or a gas (vapour).

But there was a time when it went unappreciated…

Early Days of Wasted LPG

LPG is not a by-product.

LPG is a valuable co-product of the natural gas processing and crude oil refinery process that comes from a deliberate liquefied petroleum gas production process (LPG production).

LPG is a valuable co-product of the natural gas processing and crude oil refinery process that comes from a deliberate liquefied petroleum gas production process (LPG production).

In the early days of the oil refinery business, there wasn’t an established infrastructure or market for LPG.

The same was true of natural gas (methane).

As a result, the LPG and methane were wasted through flaring — the burning off of the unwanted gas when liquid petroleum gas is made (LPG is made) .

This early practice from long, long ago led some people to refer to LPG as a by-product.

Sadly, flaring still goes on in some countries.

LPG Process – LPG Stripped from Natural Gas

Separating the Gas from the Oil

When liquid petroleum gas is made (LPG is made) , the gas/oil mixture is piped out of the well and into a gas trap, natural gas processing separates the stream into crude oil and “wet” gas, which contains LPG and natural gas.

This is a precursor to liquefied petroleum gas production process (LPG gas production).

The heavier crude oil sinks to the bottom of the trap and is then pumped into an oil storage tank to the oil refinery.

The “wet” gas, off the top of the gas trap, goes through a production process to separate the gasoline (petrol) from the natural gas and LPG.

Methane Production Process – Natural Gas Processing – Pipeline Quality Dry Natural Gas

Raw natural gas processing which starts at the well head with methane, ethane, ethene, propene, isobutene, butadiene, pentane, pentene and impurities.

The non-methane hydrocarbons must be separated from the methane.

Impurities such as water, carbon dioxide, nitrogen and hydrogen sulfide must be removed by further natural gas processing before either the refined pipeline quality dry natural gas (methane) can be used or the LPG production process (LPG gas production) begun.

After the completion of natural gas processing, the refined and purified natural gas, which is mostly methane, pipeline quality dry natural gas is fed into the pipelines that supply our cities and towns.

Distribution of refined pipeline quality dry natural gas (methane) is typically handled by gas utility companies.

LPG Production from Raw Natural Gas made of 8 Hydrocarbons

Refined natural gas is made of methane.

LPG production process (liquefied petroleum gas production process) involves separating the raw natural gas made of an intricate mixture of hydrocarbons, which includes the methane, ethane, ethene, propene, isobutene, butadiene, pentane, and pentene.

The liquefied petroleum gas production process (LPG gas production) plants are frequently called “stripper plants”, as the LPG is made of or stripped from the natural gas processing flow using the LPG manufacturing process.

Impurities must also be removed from the LPG products propane and butane or they will prevent the LPG from liquefying properly.

A refrigeration based LPG gas manufacturing process (LPG production) is common for recovery of LPG from a natural gas stream.

With this technique, the LPG production process (liquefied petroleum gas production process) refrigerates the gas stream to obtain the LPG products.

Refrigeration is employed in three different LPG gas production process (LPG production): expander plants, low temperature separation and combined processes.

Other LPG gas production process (LPG production) separation techniques may also be employed, including lean oil absorption.

This LPG can be used as a mixture or further separated into the LPG products propane, butane and isobutane, as needed.

The LPG products enter their own distribution network, where they eventually find the way to end users, including 45kg home LPG and commercial LPG users all around Australia and the world.

LPG Production Process (LPG Gas Production) from Fractional Distillation of Crude Oil – NGL Fractionation Process

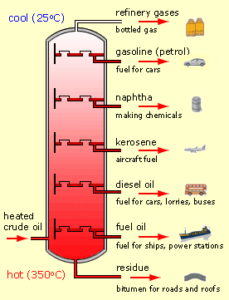

Crude oil refining process includes a variety of refining processes including fluid catalytic cracking, delayed cokers, and fractional distillation of crude oil.

LPG is one of the refined products obtained from this LPG gas manufacturing (LPG gas production) process (NGL fractionation process).

LPG is one of the refined products obtained from this LPG gas manufacturing (LPG gas production) process (NGL fractionation process).

After desalting, the heated crude oil is pumped into the distillation tower for fractional distillation of crude oil.

In the liquefied petroleum gas production process (LPG production), fractions of the flow are obtained from the side of the distillation tower at various heights between the bottom and the top.

Each extraction point in the LPG production (LPG gas production) process (NGL fractionation process) is temperature controlled to obtain a specific fraction including gasoline, naphtha, kerosene, diesel, light gas oil and heavy gas oil.

These are then sent to unique streams for storage or possible further processing.

LPG Gas Production (LPG Production) for Refining

LPG, with the lowest boiling point, is obtained from the top of the distillation tower, using the LPG production (LPG gas production) process (fractional distillation of crude oil).

This LPG product component can be used as a mixture or further separated into its three primary parts: propane, butane and isobutane.

This further liquefied petroleum gas production (LPG production) process fractionation can be achieved with Depropaniser, Debutaniser and Deisobutaniser fractionators.

How is LPG Transported

To transport or store it, LPG gas needs to be liquefied under pressure.

LPG can be stored or transported in LPG gas cylinders or vessels.

LPG (propane) can be transported in a number of ways, including by ship, rail, tanker trucks, intermodal tanks, cylinder trucks, pipelines and local gas reticulation systems.

Final Thoughts on the LPG Origin and Liquefied Petroleum Gas Production – LPG Production

For something that exists naturally, LPG origin, the LPG production (LPG gas production) process (liquefied petroleum gas production process) is complex and takes a lot of work to get LPG products to the point of use.

However, its clean burning, portability and versatility truly makes LPG worth the effort.